As the demand for portable energy systems and mobile power grows—from RVs to marine vessels, overland vehicles, and solar installations—the need for safe, durable, and efficient battery storage solutions becomes crucial. Enter the aluminum battery box: a rugged, lightweight, and corrosion-resistant enclosure designed to protect your batteries in the harshest environments.

This article explores what aluminum battery boxes are, why they matter, and how they compare to other materials like plastic or steel.

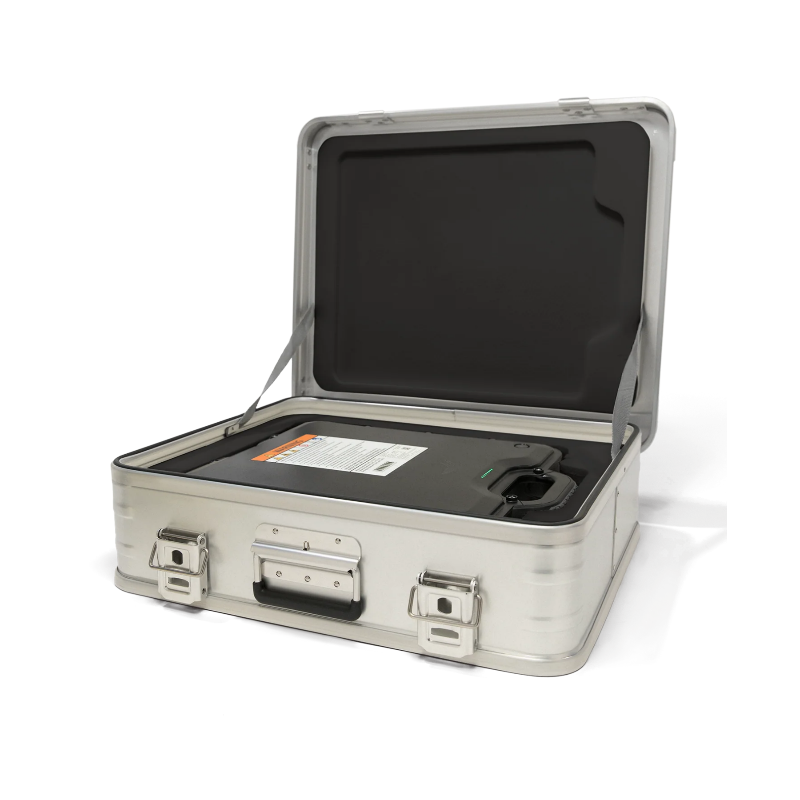

What Is an Aluminum Battery Box?

An aluminum battery box is a protective enclosure made from aluminum alloy, specifically designed to house and secure batteries. These boxes are often used in applications such as:

RVs and campervans

Off-grid solar systems

Boats and marine environments

Overland trucks and UTVs

Racing and drag cars

Backup power stations

They come in various sizes to fit common battery types such as AGM, lithium-ion (LiFePO4), gel, or lead-acid batteries.

Key Advantages of Aluminum Battery Boxes

1. Lightweight but Strong

Aluminum offers an ideal strength-to-weight ratio. Compared to steel boxes, aluminum is up to 60% lighter but still highly durable—perfect for mobile applications where every pound matters.

2. Corrosion Resistance

Unlike steel, aluminum doesn’t rust. This makes aluminum battery boxes an excellent choice for marine or coastal use, where saltwater corrosion is a major concern.

3. Heat Dissipation

Batteries generate heat during charging and discharging. Aluminum naturally dissipates heat more effectively than plastic, helping prevent overheating and extending battery lifespan.

4. Secure Mounting and Protection

Aluminum boxes often feature reinforced corners, locking lids, venting options, and pre-drilled holes for secure mounting. This keeps batteries safe from vibration, impact, and environmental damage.

5. Customizability

Aluminum is easy to fabricate and weld, allowing for custom battery box designs with cable ports, mounting brackets, or multiple compartments for hybrid systems.

Common Applications

RVs and Campers

Aluminum battery boxes are mounted under the chassis or inside compartments to house lithium house batteries, protecting them from road debris and weather exposure.

Boats and Marine Use

Saltwater, moisture, and vibration demand a corrosion-proof and sealed box—aluminum offers the durability needed for onboard battery systems.

Off-Grid Solar Systems

Used to protect solar storage batteries, especially in outdoor or semi-permanent installations. Boxes can be locked to prevent theft and intrusion.

Performance and Racing

Drag and off-road vehicles use aluminum battery boxes to relocate and securely house batteries in the trunk or rear of the vehicle for better weight distribution and safety.

Aluminum vs. Other Battery Box Materials

| Feature | Aluminum | Plastic | Steel |

|---|---|---|---|

| Weight | Lightweight | Very lightweight | Heavy |

| Durability | High | Medium | Very high |

| Corrosion Resistance | Excellent | Excellent | Poor (unless coated) |

| Heat Dissipation | Good | Poor | Moderate |

| Cost | Moderate to high | Low | Low to moderate |

| Customizability | High (can be welded/cut) | Low (injection molded) | Moderate |

What to Look for in an Aluminum Battery Box?

When shopping for or building an aluminum battery box, consider:

Battery Size & Type: Match the box size to your battery (e.g., Group 31, 12V 100Ah, etc.)

Ventilation Needs: Lead-acid batteries may need venting; lithium batteries often don’t.

Locking Mechanism: For theft prevention and tamper resistance.

Mounting Hardware: Choose boxes with tabs or bolt holes for secure installation.

Cable Entry Ports: Rubber grommets or watertight entry points for safe wiring.

Requirements of Aluminum Battery Boxes' Fireproof and Explosion-Proof Lining

As the demand for electric vehicles (EVs) and energy storage systems continues to surge, ensuring the safety and reliability of battery enclosures has become a critical priority. Among various materials used for battery housing, aluminum battery boxes are widely adopted due to their lightweight, corrosion resistance, and thermal conductivity. However, to mitigate thermal runaway events, fires, and explosions, these enclosures must be equipped with fireproof and explosion-proof linings that meet stringent safety standards.

This article explores the key requirements of such linings, highlighting the materials, design criteria, and performance expectations necessary to ensure safe operation under extreme conditions.

Why Fireproof and Explosion-Proof Linings Are Needed

The Risk:

Thermal runaway in lithium-ion batteries can cause temperatures to exceed 600°C (1112°F).

The decomposition of battery cells releases flammable gases and toxic byproducts.

Without proper containment, this can result in fires, explosions, and chain reactions.

The Role of Lining:

The lining acts as a critical safety barrier:

Delays or prevents heat penetration to the exterior.

Contains pressure build-up during an internal explosion.

Limits the spread of fire to adjacent cells or external environments.

Aluminum Battery Boxes' Lining the Flame Test on YouTube.com

Key Requirements of Fireproof & Explosion-Proof Linings

1. High Thermal Resistance

Must withstand temperatures above 1000°C for short durations without structural failure.

Should have a low thermal conductivity (<0.05 W/m·K) to reduce heat transfer to the aluminum shell.

Common Materials: Ceramic fiber, aerogel composites, mica plates, intumescent coatings.

2. Mechanical Strength & Integrity

Lining must retain its shape and performance under mechanical stress, including vibration, impact, or deformation.

Should maintain integrity even during battery cell expansion or bursting.

Design Consideration:

Use of reinforced structures (e.g., fiber mesh or aluminum foil backing).

Adherence to ASTM and ISO impact resistance standards.

3. Chemical Compatibility

Must resist chemical degradation from battery electrolytes, vapors, or corrosive gases.

No outgassing or decomposition that might contribute to fire propagation.

Material Selection Tip: Avoid organic compounds that degrade under high temperatures or react with lithium or fluorinated compounds.

4. Explosion Containment Capacity

Ability to absorb or redirect pressure waves from internal explosions.

Should include pressure relief features (vents, burst panels) integrated with the lining material or design.

Testing Standard: IEC 62660-2, UL 2580 for battery abuse and explosion containment.

5. Flame Retardancy and Self-Extinguishing Behavior

Linings must be non-flammable or self-extinguishing under direct flame exposure.

Must meet certifications such as UL 94 V-0, EN 13501, or NFPA 130 for fire safety in enclosures.

6. Weight and Space Efficiency

While adding a safety layer, linings must not significantly increase the overall weight or volume of the battery pack.

Optimal fireproof materials balance performance and thickness, typically ≤5 mm for most vehicle applications.

7. Ease of Manufacturing and Integration

Materials should be easy to cut, form, and adhere to the inner surface of aluminum enclosures.

Compatibility with automated assembly and modular battery designs is highly desirable.

Examples: Pre-formed panels, spray-on ceramic coatings, or adhesive-backed insulation sheets.

8. Durability Over Lifecycle

The lining must maintain its fireproof and explosion-proof properties over 10+ years or the lifetime of the battery system.

Must endure thermal cycling, humidity, road vibration, and aging effects without degradation.

Standards and Compliance Guidelines

| Standard | Scope |

|---|---|

| UL 94 | Flame classification for plastic materials |

| UL 2580 | Battery safety for EVs |

| UN 38.3 | Transportation safety of lithium batteries |

| IEC 62660-2 | Mechanical and abuse tests for lithium cells |

| ISO 12405 | Test procedures for battery packs and systems |

Industry Trends

Advanced Aerogel Linings: Extremely lightweight and thermally resistant, now used in premium EV applications.

Multi-layered Composites: Combine thermal barriers, pressure-resistant sheets, and chemical shields in a single lining.

Smart Linings: Research is underway for sensor-integrated fireproof layers that can provide early thermal warnings.

The fireproof and explosion-proof lining of aluminum battery boxes is not just an accessory—it is a core component of battery safety design. As battery energy densities increase, so does the importance of using high-performance insulation materials that provide multi-functional protection without compromising space or weight.

By understanding and implementing the right requirements—thermal, mechanical, chemical, and regulatory—manufacturers can significantly enhance the safety, durability, and market acceptance of energy storage systems across industries.

Final Thoughts

Aluminum battery boxes are an investment in safety, durability, and performance. Whether you're outfitting a solar trailer, racing car, or expedition truck, choosing the right enclosure ensures your batteries are protected, your system runs efficiently, and your gear lasts longer.

They may cost more than plastic alternatives, but in terms of strength, reliability, and long-term value, aluminum battery boxes are hard to beat.

KASSICO, a leading custom case factory in Ningbo, China since 2001, specializes in manufacturing custom plastic cases, aluminum storage boxes, aluminum tool boxes, coolers for daily organization, outdoors, camping, overlanding, military, medical, etc. We supply full custom service, including developing OEM & ODM projects. Our company owns a 15000m2 factory area and more than 200 sets of advanced manufacturing equipment. A perfect and rigorous QC system is implemented in every process from material purchasing to finished product packaging.

English

English German

German Spanish

Spanish